How to Use Box Templates to Get Perfect Packaging for Your Business UK

September 20, 2025

Good packaging starts with good design. Using the right box template can save time, reduce costly mistakes, and help your food arrive safely—while looking sharp and professional. In this post, Custom Supplies UK explains what box templates are, why they matter, and where you can find or create them to match your brand’s needs.

What Are Box Templates?

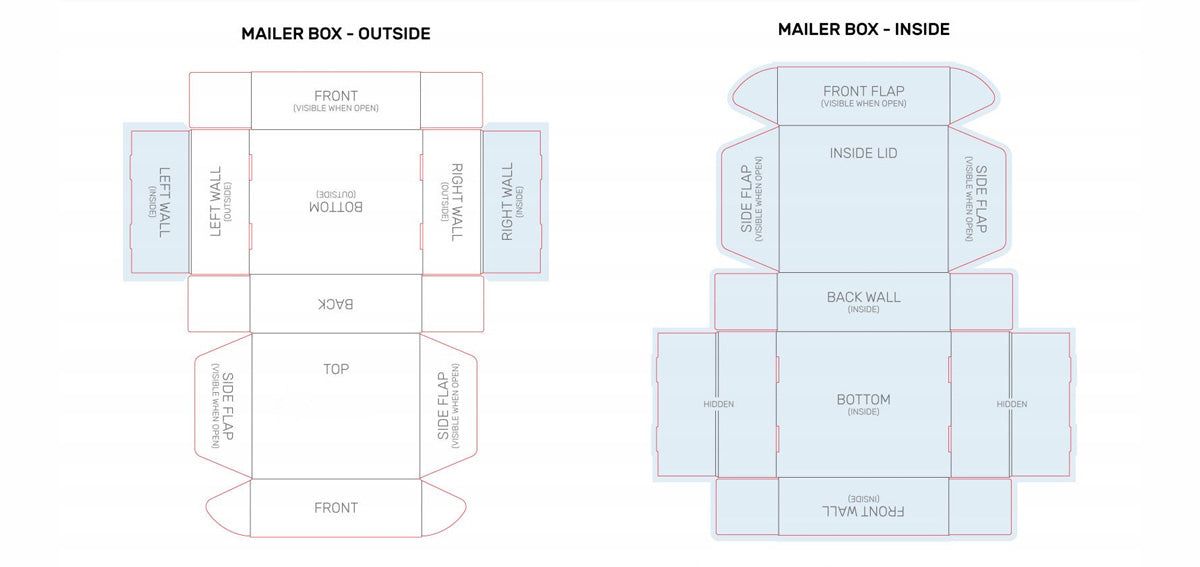

A box template (or dieline) is a flat layout that shows where cuts, folds, flaps, and creases of a packaging box will be. Think of it as the blueprint of your box—it ensures every decision from size to fold lines to glue areas is clearly mapped out before production.

Templates include:

-

Plain shapes: rectangular, square, hexagon etc.

-

Style-specific layouts: tuck-end, clamshell, pizza box flaps, fold-over lids etc.

-

Lines for gluing, slots, windows, ventilation holes, flaps etc.

Using accurate templates means your final box will assemble correctly, close properly, protect the food, and not waste material.

Why Templates Matter for Food Packaging

For businesses that make or deliver food in the UK (restaurants, pizzerias, cafés, bakeries etc.), getting the template right brings several benefits:

|

Benefit |

Why It’s Important |

|

Reduce Waste & Mistakes |

Fewer mis-cuts, fewer returns, less material wasted because fit + closure is tested on template. |

|

Improve Fit & Protection |

Ensures internal space matches your food, allows for inserts / lids, helps avoid squashing toppings, leaking sauce etc. |

|

Better Branding |

Precise logo placement, window cut-outs, folding patterns etc. work better when template is precise. |

|

Time & Cost Savings |

Quicker turnaround when the production process already has correct dieline; fewer revisions. |

Where to Find or Create Templates

Here are reliable methods and platforms to get box templates that match your requirements:

-

Online Template Generators

-

Use tools where you input your dimensions, material thickness etc., and receive ready-made dielines.

-

Example: Tools for bag and box templates, standard flap-boxes etc.

-

Premium Template Libraries / Marketplace Platforms

-

Suppliers often offer basic dielines.

-

For custom shapes or branded boxes, you can purchase or license templates from design marketplaces.

-

Hiring a Designer

-

When your box design is unique (custom flap shape, unusual size, inserts etc.), a packaging designer can draw custom dielines to specification.

-

Platforms like Fiverr, Upwork, or specialist packaging designers.

-

Design Software

-

If you or someone in your team is comfortable with tools like Adobe Illustrator or InDesign, you can build precise templates in house.

-

For more complex packaging, specialized CAD tools like ArtiosCAD or Esko can help.

-

DIY / Hybrid Methods

-

Print basic template, mock-up with cardboard, test with food item, adjust.

-

Use software + physical sample to check fit, closure, dimensions.

What to Include in a Good Box Template

To ensure your template works well and avoids costly redesigns, make sure it includes:

-

Correct panel sizes: front, back, sides, lid etc.

-

Flap glue areas.

-

Fold / crease lines.

-

Cut-outs or windows if required.

-

Material thickness specification (so you know internal vs external space).

-

Safe zones and bleed for printing (so logo/design doesn’t get cut off).

-

Spaces for food safety / instructions or branding, ventilation etc.

Common Template Mistakes & How to Avoid Them

|

Mistake |

How to Avoid |

|

Leaving out material thickness |

Always add material thickness to dimensions so fold lines and sizing are accurate. |

|

Ignoring internal space needed for inserts / liners |

Measure product + lining + any inserts to ensure everything fits. |

|

Using a template that doesn’t close well |

Mock up physical sample before placing large order. |

|

Poor printing bleed / design margins |

Include printing bleed and safe zone in template. |

|

Choosing wrong style (flaps, clamshell vs tuck-end etc.) |

Test with product + closure type to see which handles contents best. |

How Custom Supplies UK Helps with Templates

At Custom Supplies UK, we assist you in getting the right template every time:

-

We provide free basic dielines for many of our box styles (pizza boxes, burger boxes, custom takeaway cartons etc.).

-

You can submit your product dimensions, and our design team will generate a template mock-up to test size, flap closure, design position.

-

We support tweaks: adding branding, window cut-outs, inserts etc.

-

Prior to large production runs, we offer sample boxes so you can test assembly, fit, strength.

Practical Steps to Use a Template in Your Design Process

-

Measure your product carefully (length, width, height), including any liner or insert.

-

Choose a box style (tuck-end, clamshell, pizza box, etc.) based on product type.

-

Get or generate the template based on those measurements.

-

Mock up a sample physically (fold, assemble, insert product).

-

Check design placement: logo, print bleed, color alignment.

-

Adjust if needed: modify flap size, internal height, etc.

-

Approve template for production.

Final Thoughts

Box templates might seem technical or minor — but they are the backbone of good packaging. A well-designed template means your food gets delivered safely, branding looks sharp, costs stay low, and customer perception improves.

If you’re ready to move from generic to precisely fitted packaging, Custom Supplies UK is here to help every step of the way. Whether you need a custom template or a sample to test—get in touch with us and let’s create packaging that’s designed for your product.